CHAPTER 12

GENERAL SHOP INSTRUCTIONS

CHARGING BATTERIES

The equipment for charging batteries, instructions for building and wiring charging benches have already been given. What we shall now discuss is the actual charging. The charge a battery receives on the charging bench is called a "bench charge."

Battery charging in the service station may be divided into two general classes:

1. Charging batteries which have run down, but which are otherwise in good condition, and which do not require repairs.2. Charging batteries during or after the repair process.

The second class of charging is really a part of the repair process and will-be described in the chapter on "Rebuilding the Battery." Charging a battery always consists of sending a direct current through it, the current entering the battery at the positive terminal and leaving it at the negative terminal, the charging current, of course, passing through the battery in the opposite direction to the current which the battery produces when discharging. When a battery discharges chemical changes take place by means of which electrical energy is produced. When a battery is on charge, the charging current causes chemical changes which are the reverse of those which take place on discharge and which put the active materials and electrolyte in such a condition that the battery serves as a source of electricity when replaced in the car.

Batteries are charged not only in a repair shop but also in garages which board automobiles, and in car dealers' shops. No matter where a battery is charged, however, the same steps must be taken and the same precautions observed.

When a Bench Charge is Necessary:

(a) When a battery runs down on account of the generator on the car not having a sufficient output, or on account of considerable night driving being done, or on account of frequent use of the starting motor, or on account of neglect on the part of the car owner.

(b) Batteries used on cars or trucks without a generator, or batteries used for Radio work should, of course, be given a bench charge at regular intervals.

(c) When the specific gravity readings of all cells are below 1.200, and these readings are within 50 points of each other.

Should the gravity reading of any cell be 50 points lower or higher than that of the other cells, it is best to make a 15-seconds high rate discharge test (see page 266) to determine whether the cell is defective or whether electrolyte has been lost due to flooding caused by over-filling and has been replaced by water or higher gravity electrolyte. If any defect shows up during the high rate test, the battery should be opened for inspection. If no defect shows up, put the battery on charge.

(d) When the lamps burn dimly while the engine is running.

(e) When the lamps become very dim when the starting switch is closed.

If a battery is tested by turning on the lights and then closing the starting switch, make sure that there is no short-circuit or ground in the starting motor circuits. Such trouble will cause a very heavy current to be drawn from the battery, resulting in a drop in the voltage of the battery.

(f) When the voltage of the battery has fallen below 1.7 volts per cell, measured while all the lights are turned on.

(g) When the owner has neglected to add water to the cells regularly, and the electrolyte has fallen below the tops of the plates.

(h) When a battery has been doped by the addition of electrolyte or acid instead of water, or when one of the "dope" electrolytes which are advertised to make old, worn out batteries charge up in a ridiculously short time and show as much life and power as a new battery. Use nothing but a mixture of distilled water and sulphuric acid for electrolyte. The "dope" solutions are not only worthless, but they damage a battery considerably and shorten its life. Such a "doped" battery may give high gravity *readings and yet the lamps will become very dim when the starting motor cranks the car, the voltage per cell will be low when the lights are burning, or low voltage readings (1.50 per cell) will be obtained if a high rate discharge test is made.

Every battery which comes in for any reason whatsoever, or any battery which is given a bench charge whenever necessary should also be examined for other defects, such as poorly burned on connectors and terminals, rotted case, handles pulled off, sealing compound cracked, or a poor sealing job between the covers and jars, or covers and posts. A slight leakage of electrolyte through cracks or imperfect joints between the covers and jars or covers and posts is very often present without causing any considerable trouble. If any of the other troubles are found, however, the battery needs repairing.

Arrangement of Batteries on Charging Bench. If a battery comes in covered with dirt, set it on the wash rack or in the sink and clean it thoroughly before putting it on charge. In setting the batteries on the charging bench, place all of them so that the positive terminal is toward the right as you face the bench. The positive terminal may be found to be painted red, or may be stamped "+", "P", or "POS". If the markings on one of the terminals has been scratched or worn off, examine the other terminal. The negative terminal may be found to be painted black, or be stamped "-", "N" or "NEG".

If neither terminal is marked, the polarity may be determined with a voltmeter, or by a cadmium test. To make the voltmeter test, hold the meter wires on the battery terminals, or the terminals of either end cell. When the voltmeter pointer moves to the right of the "0" line on the scale, the wire attached to the "+" terminal of the meter is touching the positive battery terminal, and the wire attached to the "-" terminal of the meter is touching the negative battery terminal. If this test is made with a meter having the "0" line at the center of the scale, be sure that you know whether the pointer should move to the left or right of the "0" line when the wire attached to the "+" meter terminal is touching the positive battery terminal.

Another method of determining which is the positive terminal of the battery is to use the cadmium test. When a reading of about two volts is obtained, the prod held on one of the cell terminals is touching the positive terminal. When a reading of almost zero is obtained, that is, when the needle of the meter just barely moves from the "0" line, or when it does not move at all, the prod held on one of the cell terminals is touching the negative terminal. This test, made while the battery is on open-circuit, is not a regular cadmium test, but is made merely to determine the polarity of the battery.

The polarity of the charging line will always be known if the bench is wired permanently. The positive charging wire should always be to the right. If a separate switch is used for each battery (Figures 43 and 65), the wire attached to the right side of the switch is positive. If the batteries are connected together by means of jumpers (Figures 44 and 47), the positive charging wire should be at the right hand end of the bench as seen when facing the bench. If a constant-potential charging circuit is used as shown in Figure 48, the positive bus-bar should be at the top and the neutral in the center, and the negative at the bottom.

If the polarity of the charging line wires is not known, it may be determined by a voltmeter, in the same way as the batter-, polarity is determined. If this is done, care should be taken to use a meter having a range sufficient to measure the line voltage. If no such voltmeter is available, a simple test is to fill a tumbler with weak electrolyte or salt water and insert two wires attached to the line. The ends of these wires should, of course, be bare for an inch or more. Hold these wires about an inch apart, with the line alive. Numerous fine bubbles of gas will collect around the negative wire.

With the polarities of all the batteries known, arrange them so that all the positive terminals are at the right. Then connect them to the individual switches (see Figure 43), or connect them together with jumpers (see Figure 44), being sure to connect the negative of one battery to the positive of the next. Connect the positive charging line wire to the positive terminal of the first battery, and the negative line wire to the negative terminal of the last battery. See page 105.

With all connections made, and before starting to charge, go over all the batteries again very carefully. You cannot be too careful in checking the connections, for if one or more batteries are connected reversed, they will be charged in the wrong direction, and will most likely be severely damaged.

As a final check on the connections of the batteries on the line, measure the total voltage of these batteries and see if the reading is equal to two times the total number of cells on the line.

Now inspect the electrolyte in each cell. If it is low, add distilled water to bring the electrolyte one-half inch above the plates. Do not wait until a battery is charged before adding water. Do it now. Do not add so much water that the electrolyte comes above the lower end of the vent tube. This will cause flooding.

Charging, Rate. If you connect batteries of various sizes together on one circuit, charge at the rate which is normal for the smallest battery. If the rate used is the normal one for the larger batteries, the smaller batteries will be overheated and "boiled" to death, or they may gas so violently as to blow a considerable portion of the active material from the plates.

It is quite possible to charge 6 and 12 volt batteries in series. The important point is not to have the total number of cells too high. For instance, if the 10 battery Tungar is used, ten 6-volt batteries (30 cells), or any combination which gives 30 cells or less may be used. For instance, five 12-volt batteries (30 cells), or six 6-volt batteries (18 cells) and two 12-volt batteries (12 cells), or any other combination totaling 30 cells may be used. The same holds true for motor-generators.

The charging rate is generally determined by the size of the charging outfit. The ten battery Tungar should never have its output raised above 6 amperes. A charging rate of 6 amperes is suitable for all but the very smallest batteries. In any case, whether you are certain just what charging rate to use, or not, there are two things which will guide you, temperature and gassing.

1. Temperature. Have a battery thermometer (Figure 37) on hand, and measure the temperature of the electrolyte of each cell on the line. If you note that some particular cell is running hotter than the others, keep the thermometer in that cell and watch the temperature. Do not let the temperature rise above 110 degrees Fahrenheit, except for a very short time. Should the highest of the temperature of the cells rise above 110 degrees, reduce the charging rate.

2. Gassing. Near the end of a charge and when the specific gravity has stopped rising, or is rising very slowly, bubbles of gas will rise from the electrolyte, this being due to the charging current decomposing the water of the electrolyte into hydrogen and oxygen. If this gassing is too violent, a considerable amount of active material will be blown from the plates. Therefore, when this gassing begins, the charging rate should be reduced, unless the entire charging has been done at a low rate, say about five amperes.

If gassing begins in any cell soon after the charge is started, or before the specific gravity has reached its highest point, reduce the charging rate to eliminate the gassing.

If one battery or one cell shows a high temperature and the others do not, or begins gassing long before the others do, remove that battery from the charging line for further investigation and replace it with another so as not to slow up the charge of the other batteries which are acting normally.

As long as excessive temperatures and too-early gassing are avoided, practically any charging rate may be used, especially at the start. With a constant potential charging set, as shown in Figure 48, the charge may start at as high a rate as 50 amperes. If this system of charging is used, the temperature must be watched very carefully and gassing must be looked for. With the usual series method of charging, a charge may, in an emergency, be started at 20 amperes or more. As a general rule do not use a higher rate than 10 amperes. A five ampere rate is even better, but more time will be required for the charge.

Time Required for a Charge. The time required is not determined by the clock, but by the battery. Continue the charge until each cell is gassing freely (not violently) and for five hours after the specific gravity has stopped rising. The average condition of batteries brought in for charge permits them to be fully charged in about 48 hours, the time being determined as stated above. Some batteries may charge fully in less time, and some may require from four days to a week, depending entirely upon the condition of the batteries. Do not give any promise as to when a recharge battery will be ready. No one can tell how long it will take to charge.

Specific Gravity at the End of the Charge. The specific gravity of the electrolyte in a fully charged cell should be from 1.280 to 1.300. If it varies more than 10 points above or below these values, adjust it by drawing off some of the electrolyte with a hydrometer and adding water to lower the gravity, or 1.400 acid to raise the gravity. After adjusting the gravity charge for one hour more.

Battery Voltage at End of Charge. The voltage of a fully charged cell is from 2.5 to 2.7 when the temperature of the electrolyte is 80 degrees Fahrenheit; 2.4 to 2.6 when the temperature of the electrolyte is 100 degrees Fahrenheit, and 2.35 to 2.55 volts when the temperature of the electrolyte is 120 degrees Fahrenheit, and this. voltage, together with hydrometer readings of 1.280-1.300 indicate that the battery is fully charged.

Just before putting a battery which has been charged into service, give it a 15 seconds high rate discharge test, see page 266.

Painting. Before returning a battery to the owner wipe it perfectly clean and dry. Then wipe the covers, terminals, connectors and handles with a rag wet with ammonia. Next give the case a light coat of black paint which may be made by mixing lamp black and shellac. This paint dries in about five minutes and gives a good gloss. The customer may not believe that you are returning the battery which he brought in but he will most certainly be pleased with your service and will feel that if you take such pains with the outside of his battery you will certainly treat the inside with the same care when repairs are necessary. The light coat of paint costs very little for one battery, but may bring you many dollars worth of work.

Level of Electrolyte. During charge the electrolyte will expand, and will generally flow out on the covers. This need not be wiped off until the end of the charge. When the electrolyte has cooled after the battery is taken off charge, it must be about 1/2 inch above the plates. While the electrolyte is still warm it will stand higher than this, but it should not be lowered by drawing off some of it, as this will probably cause it to be below the tops of the plates and separators when it cools.

If all goes well, the charging process -will take place as described in the preceding paragraphs. It frequently happens, however, that all does not go well, and troubles arise. Such troubles generally consist of the following:Specific gravity will not rise to 1.280. This may be due to the plates not taking a full charge, or to water having been used to replace electrolyte which has been spilled. To determine which of these conditions exist, make cadmium test (see page 174) on the positives and negatives, also measure the voltage of each cell. If these tests indicate that the plates are fully charged (cell voltage 2.5 to 2.7, Positive-Cadmium 2.4 volts, Negative-Cadmium minus 0.15 to 0.20 volts), you will know that there is not enough acid in the electrolyte. The thing to do then is to dump out the old electrolyte, refill with 1.300 electrolyte and continue the charge until the specific gravity becomes constant. Some adjustment may then have to be made by drawing off some of the electrolyte with a hydrometer and adding water to lower the gravity, or 1.400 acid to bring it up. Remember that specific gravity readings tell you nothing about the plates, unless it is known that the electrolyte contains the correct proportions of water and acid. The cadmium test is the test which tells you directly whether or not the plates are charged and in charging a battery the aim is to charge the plates, and not merely to bring the specific gravity to 1.280.

If the specific gravity will not rise to 1.280 and cadmium tests show that the plates will not take a full charge, then the battery is, of course, defective in some way. If the battery is an old one, the negatives are probably somewhat granulated, the positives have probably lost much of their active material, resulting in a considerable amount of sediment in the jars, and the separators are worn out, carbonized, or clogged with sediment. Such a battery should not be expected to give as good service as a new one, and the best thing to do if the tests show the battery to be more than half charged, is to put it back on the car, taking care to explain to the owner why his battery will not "come up" and telling him that he will soon need a new battery. Remember that improperly treated separators, or defective separators will cause poor Negative-Cadmium readings to be obtained.

If a fairly new battery will not take a full charge, as indicated by hydrometer readings and cadmium tests, some trouble has developed due to neglect, abuse, or defect in manufacture. If all cells of a fairly new battery fail to take a full charge within 48 hours, the battery has probably been abused by failing to add water regularly, or by allowing battery to remain in an undercharged condition. Such a battery should be kept on the line for several days more, and if it then still will not take a full charge the owner should be told what the condition of the battery is, and advised to have it opened for inspection.

If one cell of a battery fails to take a charge, but the other cells charge satisfactorily, and cadmium tests show that the plates of this cell are not taking a charge, the cell should be opened for inspection. If one cell of a battery charges slowly, cut the other cells out of the line, and charge the low cell in series with the other batteries on the charging line.

If all cells of a battery, whether new or old, will not take even half a charge, as indicated by hydrometer readings (1.200), the battery should be opened for inspection.

If the gravity. of a battery on charge begins to rise long before the voltage rises, and if the gravity rises above 1.300, there is too great a proportion of acid in the electrolyte. The remedy is to dump out the electrolyte, refill with pure water and continue the charge at a lower rate than before, until the specific gravity stops rising. Then charge for ten hours longer, dump out the water (which has now become electrolyte by the acid formed by the charging current), refill with about 1.350 electrolyte and continue the charge, balancing the gravity if necessary at the end of the charge.

If a battery becomes very hot while on charge at a rate which is not normally too high for the battery, it indicates that the battery is badly sulphated, or has a partial short-circuit. Gassing generally goes with the high temperature.

If you can detect a vinegar-like odor rising from the vent holes, you may be absolutely sure that the separators used in that battery have developed acetic acid due to not having received the proper treatment necessary to prepare them for use in the battery. The electrolyte should be dumped from such a battery immediately and the battery should be filled and rinsed with water several times. Then the battery should be opened without loss of time, to see whether, by removing the separators and washing the plates thoroughly, the plates may be saved. If the acetic acid has been present for any length of time, however, the plates will have been ruined beyond repair, the lead parts being dissolved by the acid.

If the electrolyte of a battery on charge has a white, milky look, there may be impurities which cause numerous minute bubbles to form, such bubbles giving the electrolyte its milky appearance. The milky appearance may be due to the use of "hard" water in refilling, this water containing lime.

The electrolyte as seen with the acid of an electric lamp or flashlight should be perfectly clear and colorless. Any scum, particles of dirt, any color whatsoever shows that the electrolyte is impure. This calls for dumping out the electrolyte, filling and rinsing with pure water, refilling with new electrolyte and putting the battery back on the charging line. Of course, this may not cause the battery to charge satisfactorily, which may be due to the troubles already described.

Should it ever happen that it is impossible to send a current through a charging circuit go over all the connections to make sure that you have good contact at each battery terminal, and that there are no loose inter-cell connectors. If all connections to the batteries are -good, and there are no loose inter-cell connectors, cut out one battery at a time until you start the current flowing, when you cut out some particular battery. This battery should then be opened without further tests, as it is without a doubt in a bad condition.

The conditions which may exist when a battery will not charge, as shown especially by cadmium tests, are as follows:

(a) The battery may have been allowed to remain in a discharged condition, or the owner may have neglected to add water, with the result that the electrolyte did not cover the plates. In either case a considerable amount of crystallized sulphate will have formed in the plates. Plates in such a condition will require a charge of about a week at a low rate and will then have to be discharged and recharged again. Several such cycles of charge and discharge may be necessary. It may even be impossible to charge such a battery, no matter how many cycles of charge and discharge are given. If the owner admits that his battery has been neglected and allowed to stand idle for a considerable time, get his permission to open the battery.

(b) The battery may have been overheated by an excessive charging rate, or by putting it on a car in a sulphated condition. The normal charging rate of the generator on the car will over heat a sulphated battery. Overheated plates buckle their lower edges cut through the separators, causing a short-circuit between plates.

(c) The pockets in the bottoms of the jars may have become filled with sediment, and the sediment may be short-circuiting the plates.

(d) Impurities may have attacked the plates and changed the active materials to other substances which do not form a battery. Such plates may be so badly damaged that they are brittle and crumbled. Acetic acid from improperly treated separators will dissolve lead very quickly, and may even cause an open circuit in the cell.

(e) The conditions described in (a), (b), and (c) will permit a charging current to pass through the battery, but the plates will not become charged. It is possible, of course, but not probable, that a condition may exist in which all the plates of one or both groups of a cell may be broken from the connecting straps, or inter-cell connectors may be making no contact with the posts. In such a case, it would be impossible to send a charging current through the battery. Acetic acid from improperly treated separators, and organic matter introduced by the use of impure water in refilling will attack the lead of the plates, especially at the upper surface of the electrolyte, and may dissolve all the plate lugs from the connecting straps and cause an open-circuit.

(f) The separators may be soggy and somewhat charred and blackened, or they may be clogged up with sulphate, and the battery may need new separators.

(g) The spongy lead may be bulged, or the positives may be buckled. The active material is then not making good contact with the grids, and the charging current cannot get at all the sulphate and change it to active material. The remedy in such a case is to press the negatives so as to force the active material back into the grids, and to put in new positives if they are considerably buckled.

(h) One of the numerous "dope" electrolytes which are offered to the trustful car owner may have been put in the battery. Such "dopes" might cause very severe damage to the plates. Tell your customers to avoid using such "dope."

The conditions which may exist when the plates of a battery take a charge, as indicated by cadmium tests, but the gravity will not come up to 1.280 are as follows:

(a) There may be considerable sediment in the jars but not enough to short circuit the plates. If the battery has at some time been in a sulphated condition and has been charged At too high a rate, the gassing that resulted will have caused chips of the sulphate to drop to the bottom of the jars. When this sulphate was formed, some of the acid was taken from the electrolyte, and if the sulphate drops from the plates, this amount of acid cannot be recovered no matter how long the charge is continued. If the owner tells you that his battery has stood idle for several months at some time, this is a condition which may exist. The remedy is to wash and press the negatives, wash the positives, put in new separators, pour out the old electrolyte and wash out the jars, fill with 1.400 acid, and charge the battery.

(b) Impurities may have used up some of the acid which cannot be recovered by charging. If the plates are not much damaged the remedy is the same as for (a). Damaged plates may require renewal.

(c) Electrolyte may have been spilled accidentally and replaced by water.

(d) Too much water may have been added, with the result that the expansion of the electrolyte due to a rise in temperature on charge caused it to overflow. This, of course, resulted in a loss of some of the acid

The causes given in (c) and (d) may have resulted in the top of the battery case being acid-eaten or rotted. The remedy in these two instances is to draw off some of the electrolyte, add some 1.400 acid and continue the charge. If plates and separators look good and there is but little sediment, this is the thing to do.

If Battery will not hold a Charge. If a battery charges properly but loses its charge in a week or less, as indicated by specific gravity readings, the following troubles may exist:

(a) Impurities in the cells, due to the use of impure water in the electrolyte, or in the separators. Some impurities (see page 76) do not attack the plates, but merely cause self-discharge. The remedy is to dump out the old electrolyte, rinse the jars with pure water, fill with new electrolyte of the same gravity as the old and recharge. If this does not remove impurities, the battery should be opened, the plates washed, jars cleaned out, new separators put in, and battery reassembled and charged.

(b) There may be a slow short-circuit, due to defective separators or excessive amount of sediment. If preliminary treatment in (a) does not cause battery to hold charge, the opening of battery and subsequent treatment will remove the cause of the slow short-circuit.

1. Make sure every battery is properly tagged before going on line.2. Determine as quickly as possible from day to day, those batteries that will not charge. Call owner and get permission to open up any such battery and do whatever is necessary to put it in good shape.

3. As soon as a battery charges to 1.280-1.300, the voltage is 2.5-2.7 per cell and the cadmium readings are 2.4 or more for the positives and -0.15 to -0.20 for the negatives and the gravity voltage and cadmium readings do not change for five hours, remove it from the line as finished and replace it with another if possible. Go over your line at least three times a day and make gravity, temperature, and cadmium tests.

4. Make a notation, with chalk, of the gravity of each cell each morning. Do not trust to memory.

5. Remove from the line as soon as possible any battery that has a leaky cell and neutralize with soda the acid that has leaked out.

6. Batteries that are sloppers, with rotten cases, and without handles are sick and need a doctor. Go after the owner and get permission to repair.

7. Keep the bench orderly and clean.

8. Remember that if you have a line only partly full and have other batteries waiting to be charged you are losing money by not keeping a full line.

9. Leave the Vent Plugs in When Charging. The atmosphere in many service stations, where the ventilation is poor, is so filled with acid fumes that customers object to doing business there.

The owners of these places may not notice these conditions, being used to it, or rather glory in being able to breathe such air without coughing or choking, but it certainly does not invite a customer to linger and spend his money.

The remedy for such a condition is to leave the vent plugs in place on the batteries that are charging so that the acid spray in the gas from the battery condenses out as it strikes these plugs and drips back into the cells, while the gas passes out through the small openings in the plug.

The plugs need only be screwed into the openings by one turn, or only set on top of the vent openings to accomplish the result.

This takes no additional time and more than repays for itself in the saving of rusted tools and improved conditions in the battery room and surroundings. In charging old Exide batteries, be sure to replace the vent plugs and turn them to open the air passages which permit the escape of gases which form under the covers. If you wish to keep these air passages open without replacing the plugs, which may be done for convenience, give the valve (see page 21) a quarter turn with a screwdriver or some other tool.

10. If the electrolyte from a battery rises until it floods over the top of the jar, it shows that too much water was added when the battery was put on charge, the water rising to the bottom of the vent tube, thereby preventing gases formed (except those directly below the vent hole) from escaping. This gas collects under the covers, and its pressure forces the electrolyte up into the vent hole and over the top of the battery. In charging old U.S.L. batteries it is especially necessary to keep the air vent (see page 20) open to prevent flooding, since the lower end of the vent tube is normally a little below the surface of the electrolyte.

Remember, do not have the electrolyte come up to the lower end of the vent tube.

NOTE: To obtain satisfactory negative cadmium readings, the charging rate should be high enough to give a cell voltage of 2.5-2.7.

Improperly treated separators, or separators which have been allowed to become partly dry at any time will make it impossible to obtain satisfactory negative cadmium readings.

Lead cannot be "burned" in the sense that it bursts into flame as a piece of paper does when a match is applied to it. If sufficient heat is applied, the lead will oxidize and feather away into a yellow looking dust, but it does not burn. The experienced battery man knows that by "lead burning" is meant the heating of lead to its melting point, so that two lead surfaces will weld together. This is a welding and not a "burning" process, and much confusion would be avoided if the term "lead welding" were used in place of the term "lead burning."The purpose of welding lead surfaces together is to obtain a joint which offers very little resistance to the flow of current, it being absolutely necessary to have as low a resistance as possible in the starting circuit. Welding also makes joints which are strong mechanically and which cannot corrode or become loose as bolted connections do. Some earlier types of starting and lighting batteries had inter-cell connectors which were bolted to the posts, but these are no longer used.

The different kinds of lead-burning outfits are listed on page 143 The oxygen-acetylene and the oxygen-hydrogen flames give extremely high temperatures and enable you to work fast. Where city gas is available, the oxygen illuminating gas combination will give a very good flame which is softer than the oxygen acetylene, oxygen-hydrogen outfits. Acetylene and compressed air is another good combination.

There are two general classes of lead-welding:

(a) Welding connecting bars, called "cell" connectors, top connectors, or simply "connectors," to the posts which project up through the cell covers, and welding terminals to the end posts of a battery.

(b) Welding plates to "straps" to form groups. The straps, of course, have joined to them the posts which project through the cell covers and by means of which cells are connected together, and connections made to the electrical system of the car.

In addition to the above, there are other processes in which a burning (welding) flame is used:

(c) Post-building, or building posts, which have been drilled or cut short, up to their original size.

(d) Extending plate lug. If the lug which connects a plate to the plate strap is too short, due to being broken, or cut too short, the lug may be extended by melting lead into a suitable iron form placed around the lug.

(e) Making temporary charging connections between cells by lightly -welding lead strips to the posts so as to connect the cells together.

(f) A lead-burning (welding) flame is also used to dry out the channel in cell covers before pouring in the sealing compound, in re-melting sealing compound which has already been poured, so as to assure a perfect joint between the compound cover and jar, and to give the compound a smooth glossy finish. These processes are not welding processes and -will not be described here.

General Lead Burning Instructions

Flame. With all the lead burning outfits, it is possible to adjust the pressures of the gases so as to get extremely hot, medium, and soft flames. With the oxygen-acetylene, or oxygen-hydrogen flame, each gas should have a pressure of about two pounds. With the oxygen-illuminating gas flame, the oxygen should have ,a pressure of 8 to 10 pounds. The city gas then does not need to have its pressure increased by means of a pump, the normal pressure (6 to 8 ounces) being satisfactory.Various makes of lead-burning outfits are on the market, and the repairman should choose the one which he likes best; since they all give good results. All such outfits have means of regulating the pressures of the gases used. With some the gases are run close to the burning tip before being mixed, and have an adjusting screw where the gases mix. Others have a Y shaped mixing valve at some distance from the burning tip, as shown in Figure 78. Still others have separate regulating valves for each gas line.

With these adjustments for varying the gas pressure, extremely hot, hissing flames, or soft flames may be obtained. For the different welding jobs, the following flames are suitable:

1. A sharp, hissing flame, having a very high temperature is the one most suitable for the first stage in welding terminals and connectors to the posts.

2. A medium flame with less of a hiss is suitable for welding plates to strips and lengthening plate lugs.

3. A soft flame which is just beginning to hiss is best for the finishing of the weld between the posts and terminals or connectors. This sort of a flame is also used for finishing a sealing job, drying out the cover channels before sealing, and so on.

In adjusting the burning- flame, 4 the oxygen is turned off entirely, a smoky yellow flame is obtained. Such a flame gives but little heat. As the oxygen is gradually turned on the flame becomes less smoky and begins to assume a blue tinge. It will also be noticed that a sort of a greenish cone forms in the center portion of the flame, with the base of the cone at the torch and the tip pointed away from the torch. At first this inner-cone is long and of almost the same color as the outer portion of the flame. As the oxygen pressure is increased, this center cone becomes shorter and of a more vivid color, and its tip begins to whip about. When the flame is at its highest temperature it will produce a hissing sound and the inner cone will be short and bright. With a softer flame, which has a temperature suitable for welding plates to a strap, the inner cone will be longer and less vivid, and the hissing will be greatly diminished.

The temperature of the different parts of the flame varies considerably, the hottest part being just beyond the end of the inner cone. Experience with the particular welding outfit used will soon show how far the tip of the torch should be held from the lead to be melted.

Cleanliness. Lead surfaces which are to be welded together must be absolutely free from dirt. Lead and dirt will not mix, and the dirt will float on top of the lead. Therefore, before trying to do any lead welding, clean the surfaces which are to be joined. -The upper ends of plate lugs may be cleaned with a flat file, knife., or wire brush. The posts and inter-cell connectors should be cleaned with a knife, steel wire brush, or triangular scraper. Do not clean the surfaces and then wait a long time before doing the lead burning. The lead may begin to oxidize if this is done and make it difficult to do a good job.

The surfaces which are to be welded together should also be dry. If there is a small hole in the top of a post which is to be welded to a connector or terminal, and this hole contains acid, a shower of hot lead may be thrown up by the acid, with possible injury to the operator.

Do not try to save time by attempting to weld dirty or wet lead surfaces, because time cannot be saved by doing so, and you run the risk of being injured if hot lead is thrown into your face. Remove absolutely every speck of dirt, --you will soon learn that it is the only way to do a good job.

Safety Precautions. Remove the vent plugs and blow down through the vent holes to remove any gases which may have collected above the surface of the electrolyte. An explosion may result if this is not done. To protect the rubber covers, you may cover the whole top of the battery except the part at which the welding is to be done, with a large piece of burlap or a towel which has been soaked in water. The parts covered by the cloth must be dried thoroughly if any welding on them. Instead of using a wet cloth, a strip of asbestos may be laid over the vent holes, or a small square of asbestos may be laid over each vent hole.

Burning on the Cell Connectors and Terminals

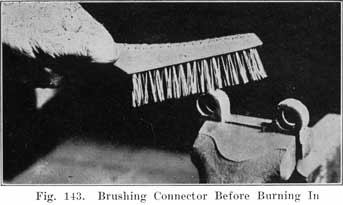

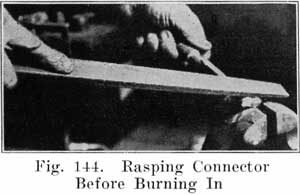

Have the posts perfectly clean and free from acid. Clean the tops, bottoms and sides of the connectors with a wire brush, Figure 143. Finish the top surfaces with a coarse file, Figure 144. With a pocket knife clean the inside surfaces of the connector holes.

Place the connectors and terminals in their proper positions on the posts, and with a short length of a two by two, two by one, or two by four wood pound them snugly in position, Figure 145. Be sure that the connectors are perfectly level and that the connectors are in the correct position as required on the car on which the battery is to be used. The top of the post should not come flush with the top of the connector. Note, from Figure 146, that the connector has a double taper, and that the lower tapered surface is not welded to the post. If the post has been built up too high it should be cut down with a pair of end cutting nippers so that the entire length of the upper taper in the connector is in plain sight when the connector is put in position on the post. This is shown in Figure 146. With the connectors in place, and before welding them to the posts, measure the voltage of the whole battery to be sure that the cells are properly connected, as shown by the voltage reading being equal to two times the number of cells. If one cell has been reversed, as shown by a lower voltage reading now is the time to correct the mistake.

|

|

|

The connectors and terminals are now ready to be welded to the posts. Before bringing any flame near the battery be sure that you have blown out any gas which may have collected under the covers. Then cover the vents with asbestos or a wet cloth. as, already described. You will need strips of burning lead, such as those made in the burning lead mould described on page 164.Use a hot, hissing flame for the first stage. With the flame properly adjusted, hold it straight above the post, and do not run it across the top of the battery. Now bring the flame straight down over the center of the post, holding it so that the end of the inner cone of the flame is a short distance above the post. When the center of the post begins to melt, move the flame outward with a circular motion to gradually melt the whole top of the post, and to melt the inner surface of the hole in the connector. Then bring the lower end of your burning lead strip close to and over the center of the hole, and melt in the lead, being sure to keep the top of the post and the inner surface of the hole in the connector melted so that the lead you are melting in will flow together and unite. Melt in lead until it comes up flush with the upper surface of the connector. Then remove the flame. This completes the first stage of the welding process. Now repeat the above operation for each post and terminal.

It is essential that the top of the post and the inner surface of the hole in the connector be kept melted as long as you are running in lead from the strip of burning lead. This is necessary to have all parts fuse together thoroughly. If you allow the top of the post, or the inner surface of the hole in the connector to chill slightly while you are feeding in the lead, the parts will not fuse, and the resuilt will be a poor Joint, which will heat up and possibly reduce the current obtained from the battery when the starting switch is closed. This reduction may prevent the starting motor from developing sufficient torque to crank the engine.

When the joint cools, the lead will shrink slightly over the center of the posts. To finish the welding, this lead is to be built up flush or slightly higher than the connector. Brush the tops of the post and connector thoroughly with a wire brush to remove any dirt which may have been floating in the lead. (Dirt always floats on top of the lead.) Soften the burning flame so that it is just barely beginning to hiss. Bring the flame down over the center of the post. When this begins to melt, move the flame outward with a circular motion until the whole top of post and connector begins to melt and fuse. If necessary run in some lead from the burning lead strip. When the post and connector are fused, clear to the outer edge of the connector, raise the flame straight up from the work.

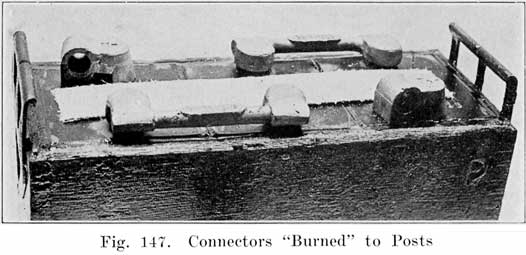

You will save time by doing the first stage of the burning on all posts first, and then finish all of them. This is quicker than trying to complete both stages of burning on each post before going to the next post. The object in the finishing stage is to melt a thin layer of the top of post and connector, not melting deep enough to have the outer edge of the connector melt and allow the lead to run off. All this must be done carefully and dexterously to do a first-class job, and you must keep the flame moving around over the top and not hold it in any one place for ally length of time, so as not to melt too deep, or to melt the outer edge and allow the lead to run off and spoil the job. Sometimes the whole mass becomes too hot and the top cannot be made smooth with the flame. If this occurs wait until the connector cools, soften the flame, and try again. Figure 147 shows the welding completed.

Burning Plates to Strap and Post

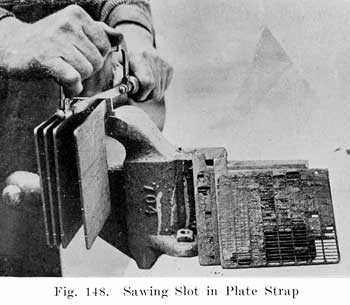

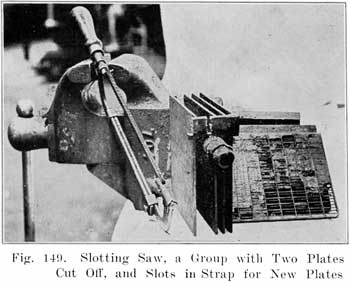

First clean all the surfaces which are to be welded together. Take your time in doing this because you cannot weld dirty surfaces together.Plates which compose a group are welded to a "strap" to which a post is attached, as shown in Figure 5. The straps shown in Figure 5 are new ones, as made in the factory. Plate lugs are set in the notches in the straps and each one burned in separately. In using old straps from a defective group, it is best to cut the strap close to the post, thus separating all the plates from the post in one operation, as was done with tile post shown in Figure 96. If only one or two plates are to be burned on, they are broken or cut off and slots cut in the strap to receive the lugs of tile new plates, as shown in Figures 148 and 149.

Set the plates in a plate burning rack, as shown in Figure 96, placing the adjustable form around the lugs and strap as shown in this figure. Be sure to set the post straight, so that the covers will fit. A good thing is to try a cover over the post to see that the post is set up properly. The post must, of course, be perpendicular to the tops of the plates. If the slotted plate strap shown in Figure 5 is used, or if one or two plates have been cut off, melt the top of the lug of one of the plates which are to be burned oil, and the surfaces of the strap to which the plate is to be welded. Melt in lead from a burning-lead strip to bring the metal up flush with the surface of the strap. Proceed with each plate which is to be burned on.If all the plates have been sawed from the strap, leaving the post with a short section of the strap attached, as shown in Figure 96, melt the edge of the strap, and the top of one or two of the end plate lugs and run in lead from the burning strip to make a good joint. Proceed in this way until all the lugs are joined to the strap and then run the flame over the top of the entire strap to make a smooth uniform weld. Be sure to have the lower edge of the strap fuse with the plate lugs and then run in lead to build the strap up to the proper thickness. Raise the flame occasionally to see that all parts are fusing thoroughly and to prevent too rapid heating.

When enough lead has been run in to build the strap tip to the correct thickness and the plate lugs are thoroughly fused with the strap, raise the flame straight up from the work. Allow the lead to "set" and then remove the adjustable form and lift the group from the burning rack. Turn the group up-side-down and examine the bottom of the strap for lead which ran down the lugs during the welding process. Cut off any such lead with a saw, as it may cause a short-circuit when the plates are meshed with the other group.

In drilling down through the inter-cell connectors to separate them from the posts in opening a battery, the posts may be drilled too short. In reassembling the battery it is then necessary to build the posts up to their original height. This is done with the aid of post-builders, shown in Figure 100.Clean the stub of the post thoroughly and also clean the inside of the post builder. Then set the post builder carefully over the stub post, so that the upper surface of the post builder is parallel to the upper surface of the plate strap. The built up post will then be perpendicular to the surface of the strap, which is necessary, in order to have the covers and connectors fit properly.

With the post builder set properly adjust the burning torch to get a sharp, hissing flame. Bring the flame straight down on the center of the post stub. When the center of the post stub begins to melt, move the flame outward with a circular motion until the whole top of the stub begins to melt. Then run in lead from a burning lead strip, Figure 101, at the same time keeping the flame moving around on the top of the post to insure a good weld. In this way build up the post until. the lead comes up to the top of the post builder. Then lift the flame straight up from the post. Allow the lead to set, and then remove the post builder, grasping it with a pair of gas or combination pliers and turn the post builder around to loosen it.

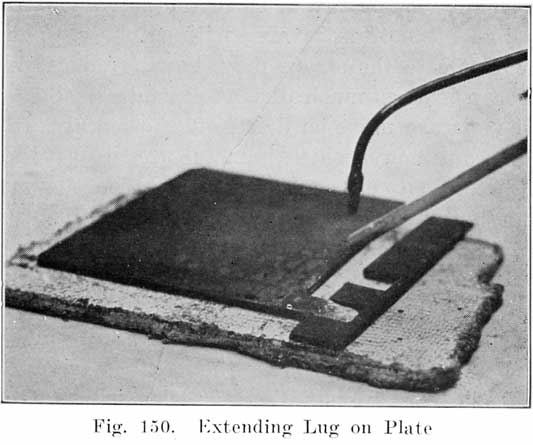

It sometimes happens that a good plate is broken from a strap, thus shortening the lug. Before the plate may be used again, the lug must be extended to its original length. To do this, clean the surfaces of the lug carefully, lay the plate on a sheet of asbestos, and place an iron form having a slot of the correct width, length, and thickness, as shown in Figure 150. Use a medium hissing flame, and melt the upper edge of the lug, and then run in lead from the lead burning strip to fill the slot in the iron form. The plate may then be used again.

Making Temporary Charging Connections

After a battery has been opened it is often desired to charge a battery without burning on the intercell connectors. Temporary connections may be made between cells by placing a short length of a burning lead strip from post to post and applying a flame for an instant to spot-weld the strip to the top of the post.

In using special moulds for casting inter-cell connectors, plate straps with posts, terminals, etc., follow the special instructions furnished by the manufacturers as to the manipulation of the special moulds made by them.Aside from the special instructions for the use of moulds, there are general rules for the melting of lead and handling it after it is melted, which must be observed if good castings are to be made.

Raw Materials. In every battery repair shop a supply of old terminals, cell connectors, posts, and straps, will gradually accumulate. These should not be thrown away or sold as junk, but should be kept in a box or jar provided for that purpose. Old plates should not be saved, since the amount of lead in the grid is small and it is often covered with sulphate. The lugs connecting the plates to the straps may, however, be used. Before using the scrap lead as much dirt as possible should be brushed off, and all moisture must be dried off thoroughly. Scrap lead contains some antimony, which is metal used to give stiffness to tile parts. Using miscellaneous scrap sometimes gives castings which do not contain the proper percentage of antimony. If there is too much antimony present, cracked castings will be the result. To remedy this condition, bars of pure lead should be purchased from some lead manufacturing company. Adding pure lead will reduce the percentage of antimony. Bars of pure antimony should also be kept oil hand in case the castings are too soft.

Lead Melting Pots are standard articles which may be purchased from jobbers. A pot having a 25 pound capacity is suitable for small shops and for larger shops a 125-pound size is best. Before melting any lead in such pots, have them thoroughly free from dirt, grease, or moisture, not merely in order to get clean castings, but also to avoid melted lead being thrown out of the pot on account of the presence of moisture. Severe burns may be the result of carelessness in this respect.

In starting with an empty melting pot, turn oil the heat before putting in any lead, and let the pot become thoroughly heated in order to drive off any moisture. With the pot thoroughly hot, drop in the lead, which must also be dry. When the metal has become soft enough to stir with a clean pine stick, skim off the dirt and dross which collects on top and continue heating the lead until it is slightly yellow oil top. Dirt and lead do not mix, and the dirt rises to the top of the metal where it may readily be skimmed off.

With a paddle or ladle, drop in a cleaning compound of equal parts of powdered rosin, borax, and flower of sulphur. Use a teaspoonful of this compound for each ten pounds of metal, and be sure that the compound is absolutely dry. Stir the metal a little, and if it is at the proper temperature, there will be a flare, flash, or a little burning. A sort of tinfoil popcorn effect will be noticed oil top of the lead. Stir until this melts down.

Have the ladle with which you dip up the melted lead quite dry. When dipping up some of the lead, skim back the dark skin which forms oil top of the lead and dip up the clean bright lead for pouring.

In throwing additional lead into a pot which is partly filled with melted lead, be sure that the lead which is thrown in the pot is dry, or else hot lead may be spattered in your face.

Have the moulds clean and dry. The parts with which the lead comes into contact should be dusted with a mould compound which fills in the rough spots in the metal so that the flow of lead will not be obstructed, and the lead will fill the mould quickly. Dip tip enough lead to fill the part of the mould you use. When you once start pouring do not, under any circumstance, stop pouring until the lead has completely filled the mould. Lead cools very quickly after it is poured into the mould, and if you stop pouring even for all instant, you will have a worthless casting.

In a shop having an ordinary room temperature, it is generally unnecessary to heat the moulds before making up a number of castings. If it is found, however, that the first castings are defective due to the cold mould chilling the lead, the mould should be heated with a soft flame. After a few castings have been made, the mould will become hot enough so that there will be no danger of the castings becoming chilled.

When the castings have cooled sufficiently to be removed, strike the mould a few blows with a wooden mallet or a rawhide hammer to loosen, the castings before opening the mould. The castings may then be removed with a screwdriver.

Cracked castings indicate that the mould was opened before the castings had cooled sufficiently, or that there is too much antimony in the castings. The remedy is to let the castings cool for a longer time, or to add pure lead to the melting pot.

The electrolyte used in the battery is made by mixing chemically pure concentrated Sulphuric Acid with chemically pure water. The concentrated acid, or "full strength" acid cannot be -used, not only because it would destroy the plates, but also because water is needed for the chemical actions which take place as a cell charges and discharges. The water therefore serves, not only to dilute the acid, but also to make possible the chemical reactions of charge and discharge.The full strength acid has a specific gravity of 1.835, and is mixed with the water to obtain the lower specific gravity which is necessary in the battery. The simplest scheme is to use only 1.400 specific gravity acid. This acid is used in adjusting the specific gravity of a battery on charge in case the specific gravity fails to rise to a high enough value. It is also used in filling batteries that have been repaired.

Acid is received from the manufacturer in ten gallon glass bottles enclosed in wooden boxes, these being called "carboys." Distilled water comes in similar bottles. When distilled in the shop, the water should be collected in bottles also, although smaller ones may be used.

Neither the acid nor the water should ever be placed in any vessels but those made of lead, glass, porcelain, rubber, or glazed earthenware. Lead cups, tanks, and funnels may be used in handling electrolyte, but the electrolyte must not be put in containers made of any metal except lead. Lead is rather expensive for making such containers, and the glass bottles, porcelain, rubber, or glazed earthenware may be used.

In mixing acid with water, pour the water in the bottle, pitcher. or jar, and then add the acid to the water very slowly. Do not pour the acid in quickly, as the mixture will become very hot, and may throw spray in your face and eyes and cause severe burns. Never add the water to the acid, as this might cause an explosion and burn your face and eyes seriously. Stir the mixture thoroughly with a wooden paddle while adding the acid. A graduate, such as is used in photography, is very useful in measuring out the quantities of acid and water. The graduate may be obtained in any size up to 64 ounces, or two quarts. In using the graduate for measuring both acid and water, be sure to use the following table giving the parts of water by volume. Although the graduate is marked in ounces, it is for ounces of water only. If, for instance, the graduate were filled to the 8 ounce mark with acid, there would be more than eight ounces of acid in the graduate because the acid is heavier than the water. But if the proportions of acid and water are taken by volume, the graduate may be used.

A convenient method in making up electrolyte, is to have a16 ounce graduate for the acid, and a 32 or 64 ounce graduate for the water. In the larger graduate pour the water up to the correct mark. In the 16 ounce graduate, pour 1.400 acid up to the 10 ounce mark. Then add the acid directly to the water in the graduate, or else pour the water into a bottle or pitcher, and add the acid to that. For instance, if we have a 32 ounce graduate, and wish to make up some 1.280 acid, we fill this graduate with water up to the 5-1/2 ounce mark. We then fill the 16 ounce graduate with 1.400 acid up to the 10 ounce mark. Then we slowly pour the 1.400 acid into the graduate containing the water, giving us 1.280 acid. In a similar manner other specific gravities are obtained, using the same amount of 1.400 acid in each case, but varying the amount of water according to the figures given in the last column of the next to the last table.

The following table shows the number of parts of distilled water to one part of 1.400 specific gravity electrolyte to prepare electrolyte of various specific gravities. The specific gravity of the mixture must be taken when the temperature of the mixture is 70° F. If its temperature varies more than 5 degrees above or below 70°F, make the corrections described on page 65 to find what the specific gravity would be if the temperature were 70° F.

BY WEIGHT

For 1.300 specific gravity use 5 ounces of distilled water for each pound of 1.400 electrolyte.For 1.280 specific gravity use 6-1/2 ounces of distilled water for each pound of 1.400 electrolyte.

For 1.275 specific gravity use 6-3/4 ounces distilled water for each pound of 1.400 electrolyte.

For 1.260 specific gravity use 7-1/2 ounces distilled water for each pound of 1.400 electrolyte.

BY VOLUME

For 1.300 specific gravity use 3-1/2 pints distilled water for each gallon of 1.400 electrolyte.For 1.280 specific gravity use 4-1/2 pints distilled water for each gallon of 1.400 electrolyte.

For 1.275 specific gravity use 5 pints distilled water for each gallon of 1.400 electrolyte.

For 1.260 specific gravity use 5-1/4 pints distilled water for each gallon of 1.400 electrolyte.

In case you wish to use other measuring- units than those given in the above table, this table may be written as follows, giving the number of parts distilled water to 10 parts of 1.400 specific gravity electrolyte:

|

Specific Gravity Desired |

Parts by Weight |

Parts by Volume |

|

1.300 |

3 |

4-1/4 |

|

1.280 |

4 |

5-1/4 |

|

1.275 |

4-1/6 |

6 |

|

1.260 |

4-7/10 |

6-1/2 |

The next table gives the number of parts of distilled water to 10 parts of concentrated sulphuric acid (which has a specific gravity of 1.835) to prepare electrolyte of various specific gravities:

|

Specific Gravity Desired |

Parts by Weight |

Parts by Volume |

|

1.400 |

8-1/2 |

15-8/10 |

|

1.300 |

13-1/2 |

25 |

|

1.280 |

15 |

27 |

|

1.270 |

16 |

28 |

|

1.260 |

17 |

30 |

PUTTING NEW BATTERIES INTO SERVICE

New batteries are received (a) fully charged and ready for service, (b) fully assembled with moistened plates and separators, but without electrolyte, (c) in a "knockdown" condition, with dry plates and without separators, (d) fully assembled with "bone dry" plates and rubber separators, and without electrolyte.Those received fully charged should be put on a car as soon as possible. Otherwise they will grow old on the shelf. Every month on the shelf is a month less of life. If the battery cannot be sold, put it into dry-storage. Batteries received in condition (b) should not be kept in stock for more than six months. Batteries received with dry plates and without separators or with rubber separators may be stored indefinitely without deteriorating.

Batteries Shipped Fully Charged, or "Wet." All Makes

Unpack the battery, keeping the packing case right side up to avoid spilling electrolyte.Brush off all excelsior and dirt, and examine the battery carefully to see if it has been damaged during shipment. If any damage has been done, claim should be made against the express or railroad company.

1. Remove the vent caps from the cells and determine the height of the electrolyte. It should stand from three-eighths to one-half inch above the tops of the plates. The level may be determined with a glass tube, as shown in Fig. 30. If the electrolyte is below the tops of the plates, it has either been spilled, or else there is a leaky jar. If all cells have a low level of electrolyte, it is probable that the electrolyte has been spilled.

2. Next measure the specific gravity of the electrolyte of each cell with the hydrometer, and then add water to bring the electrolyte up to the correct level, if this is necessary. Should the temperature of the air be below freezing, charge the battery for an hour if water is added no matter what the specific gravity readings are. This will cause the water to mix thoroughly with the electrolyte. If the battery were not charged after water is added, the water, being lighter than the electrolyte, would remain on top and freeze. For this one hour charge, use the "starting" rate, as stamped on the nameplate.

3. If the specific gravity of the electrolyte reads below 1.250, charge the battery until the specific gravity reads between 1.280 and 1.300. For this charge use the normal bench charging rates.

4. After this charge place the battery on a clean, dry spot for twenty-four hours as an extra test for a leaky jar. If there is any dampness under the battery, or on the lower part of the battery case, a leaky jar is indicated. An inspection of the level of the electrolyte, which even though no dampness shows, will show the leaky jar.

5. Just before putting the battery on the car, make the high rate discharge test on it. See page 266.

BATTERIES SHIPPED "DRY"

Exide Batteries

Storing. 1. Keep the battery in a dry, clean place, and keep the room temperature above 32 degrees, and below 110 degrees Fahrenheit.2. Put the battery into service before the expiration of the time limit given on the tag attached to the battery. The process of putting the battery into service will require about five days.

3. If the battery has been allowed to stand beyond the time limit, open up one of the cells just before beginning the process necessary to put the battery into service. If the separators are found to be cracked, split, or warped, throw away all the separators from all the cells and put in new ones. If the separators are in good condition, reassemble the cell and put the battery into service.

Putting Battery into Service. 1. Fill the cells with electrolyte of the correct specific gravity. To do this, remove the vent plugs and pour in the electrolyte until it rises to the bottom of the vent tubes. The correct specific gravities of the electrolyte to be used are as follows:

(a) For Types DX, XC, XE, XX and XXV, use 1.360 electrolyte. In tropical countries use 1.260 electrolyte.

(b) For Types LX, LXR, LXRE, LXRV, use 1.340 electrolyte. In tropical countries use 1.260 electrolyte.

(c) For Types MHA and PHC, use 1.320 electrolyte. In tropical countries use 1.260 electrolyte.

(d) For Types KXD and KZ, use 1.300 electrolyte. In tropical countries use 1.240 electrolyte.

2. After filling with the electrolyte, allow the battery to stand ten to fifteen hours before starting the initial charge. This gives the electrolyte time to cool.

3. No sooner than ten to fifteen hours after filling the battery with electrolyte, add water to bring the electrolyte up to the bottom of the vent tubes, if the level has fallen. Replace the vent caps and turn them to the right.

Start charging at the rates shown in the following table. Continue charging at this rate for at least 96 hours (4 days).

Table of Initial and Repair Charging Rates

TYPE AND SIZE OF CELL

Charging Rate-

Amperes

Minimum

Ampere Hours

1/2

50

1-1/2

145

2

190

2-1/2

240

3

290

4

385

4-1/2

430

5

480

5-1/2

525

6

575

6

575

6-1/2

625

7

675

7-1/2

720

4. Occasionally measure the temperature of the electrolyte. Do not allow the temperature to rise above 110° Fahrenheit (120° Fahrenheit in tropical countries). Should the temperature reach 110°, stop the charge long enough to allow the temperature to drop below 100°.

5. At the end of the charge, the specific gravity of the electrolyte should be between 1.280 and 1.300 (1.210 and 1.230 in tropical countries). If it is not between these limits adjust it by drawing off some of the electrolyte with the hydrometer and replacing with water if the specific gravity is too high, or with electrolyte of the same specific gravity used in filling the battery, if the specific gravity is too low.

6. Wipe off the top and sides of the battery case with a rag dampened with ammonia to neutralize any electrolyte which may have been spilled.

7. Just before putting the battery into service, give it a high rate discharge test. See page 266.

1. Remove vent caps from each cell and fill with electrolyte of 1.300 specific gravity. This electrolyte should not have a temperature greater than 75° Fahrenheit when added to the cells.2. After the addition of this acid, the battery will begin to heat and it should be left standing from 12 to 24 hours or until it has cooled off.

3. Battery should then be put on charge at the finish charging rate stamped on the name plate. Continue charging at this rate for approximately 48 to 72 hours or until the gravity and voltage readings of each cell stop rising.

4. Care should be taken to see that the temperature of battery does not rise above 110° Fahrenheit. If this occurs., the charging rate should be cut down.

5. The acid in each cell will undoubtedly have to be equalized.

6. At the finish of this developing charge the gravity should read 1.280 in each cell. If below this, equalize by putting in 1.400 specific gravity acid, or if the contrary is the case and the acid is above 1.280 add sufficient distilled water until the gravity reads 1.280.

7. After the acid has been equalized and it has stopped rising in density the voltage of each cell while still on charge at the finishing rate should read at least 2.5 volts per cell or better.

8. The battery is then ready for service. Just before putting battery into service, make a high rate discharge test on it. See page 266.

Philadelphia Diamond Grid Batteries

1. Remove the vent plugs and immediately fill the cells With electrolyte until the level is even with the bottom of the vent tube in the cover. Do not fill with electrolyte whose temperature is above 90° Fahrenheit. The specific gravity of the electrolyte to be used in starting batteries varies with the number of plates in each cell, the correct values being as follows:

Charging Rates

Fill batteries listed in Table No. 1 with 1. 270 sp. gr. acid.

TABLE -NO. 1

No. of Plates

LL-LLR

and LH

LM

LMR

LT

LTR

LS

LSR

LG

ST

LSF

9

2.0

2.5

2.0

2.5

3.0

11

2.5

3.0

2.5

3.5

4.0

13

3.0

3.5

3.0

4.0

2.5

15

3.5

4.0

3.5

4.5

5.5

17

4.0

5.0

4.0

5.5

6.0

19

4.5

5.5

4.5

6.0

Special Battery: 136 USA................6. 0 amps.

TABLE N0.2

No. of Plates

LL-LLR

and LLH

LM

LMR

LT

LTR

LS

LSR

S

SH

ST

LSF

5

1.0

1.0

2.0

1.5

7

1.5

1.5

1.5

2.0

3.0

2.0

1.5

9

4.0

11

5.0

Special Batteries: 330 AA............. 1. 0 amps.

524 STD-H2 ............ 1. 0 amps.

7 6 SPN ............ 1. 5 amps.

The number of plates per cell is; indicated in the first numeral of the type name. For instance, 712 LLA-1 is a 7 plate LL. For all lighting batteries, types S and ST. use 1.210 electrolyte.

2. Allow the battery to stand for one or two hours.

3. Remove the seal from the top of the vent caps, and open by blowing through the cap.

4. Insert vent plugs in the vent tubes.

5. Put the battery on charge at the rate given in the table on page 228. To determine the rate to use, see type name given on the battery nameplate and find correct rate in the table. Keep the battery charging at this rate throughout the charge.

6. Continue the charge until the battery voltage and the specific gravity of the electrolyte stop rising, as shown by readings taken every four hours. From three and one-half to four days of continuous charging will be required to fully charge the battery.

7. Watch the temperature of the electrolyte, and do not allow it to rise above 110° Fahrenheit. If the temperature rises to 110° F., stop the charge and allow battery to cool. Extend the time of charging by the length of time required for the battery to cool.

8. After the specific gravity of the electrolyte stops rising, adjust the electrolyte to a specific gravity of 1.280 at a temperature of 70° Fahrenheit. If the temperature is not 70°, make temperature corrections as described on page 65.

9. The battery is now ready to be installed on the car. Just before installing the battery, make a high rate discharge test on it.

A Willard Threaded Rubber insulated battery is shipped and carried in stock "bone-dry." It is filled with electrolyte and charged for the first time when being made ready for delivery.Threaded Rubber Insulated Batteries received bone-dry must be prepared for service, as follows:

1. Mix electrolyte to a density of 1.275.

2. Remove the vent plugs and fill to the top of the vent hole with 1.275 electrolyte. Be sure that the electrolyte is thoroughly mixed by stirring and that its temperature is not above 90 degrees Fahrenheit.

3. A portion of the solution will be absorbed by the plates and insulation because they have been standing dry without In-\ liquid in the cells. The volume is thus decreased, necessitating the addition of electrolyte after first filling.

Wait five minutes and then again fill to the top of the vent hole with 1.275 electrolyte.

4. The battery must now stand at least twelve hours and not more than twenty-four hours before charging,. After it has been filled an increase in temperature of the battery solution will take place. This is caused by the action of the acid in the solution penetrating the plates mid reacting with the active material, but does no injury. Since the acid in the solution joins the active material in the plates the density of the solution becomes proportionately lower. This is to be expected and should cause no concern.

In order that the entire plate volume of active material may be in chemical action during charge, the battery should stand before being placed on charge -until the solution has bad time to penetrate the entire thickness of the plates. This requires at least twelve hours, but not more than twenty-four hours.

5. Just before charging the battery, again fill with 1.275 electrolyte to 3/8 inch over the top of the separators. After this, do not add anything but distilled water to the battery solution.

6. The battery should then be put on charge at the finish rate until the gravity stops rising. At the end of this period the specific gravity should be between 1.280 and 1.300. It may take from 36 to 72 hours before this density is reached.

Care should be taken not to prolong the charging unduly, for that may cause active material to fall out of the grids, thus injuring the plates beyond repair.

7. Because of the evaporation of water in the solution during the charging process, it is necessary to add distilled water from time to time in order to keep the solution above the tops of the separators.

The temperature of the battery while on charge should never exceed 110 degrees Fahrenheit. If the temperature rises above this point the charging must be discontinued for a time or the rate decreased.

If at any time during the initial charging the density rises above 1.300 some of the solution should immediately be drawn off with a syringe and distilled water added. This must be done as often as is necessary to keep the density below 1.300.

If the specific gravity does not change after two successive readings and does not then read within the limits of 1.280 to 1.300 it should be adjusted to read correctly. If the reading is less than 1.280 it should be adjusted by drawing off as much solution as can be taken out with a syringe and electrolyte of 1.400 specific gravity added. The battery must then be placed on charge for at least four hours and another reading taken. If it is again found to be less than 1.280 this operation should be repeated as many times as necessary to bring the density up to 1.280.

9. The height of solution when taking the battery off charge should be 5/8 of an inch above the top of the separators. After the battery has been off charge long enough to permit the solution to cool to normal temperature, draw off the excess to a final height of 3/8 inch above separators. Replace the vent plugs and battery is ready for service.

Unfilled Willard Wood Insulated Batteries

Unfilled, wood-insulated batteries have not had an initial charge and require a treatment similar to batteries with threaded rubber insulation. When shipment is made in this manner, such batteries should be placed in service before the date indicated on the tag attached to the battery.To prepare such a battery for service:

1. Remove the vent plugs and fill each cell with 1.335 specific gravity electrolyte (one part of concentrated sulphuric acid by volume to two parts of distilled water by volume) to 3/8 inch above the tops of the separators.

2. Wait 5 minutes and then fill each cell again with 1.335 specific gravity electrolyte to 3/8 inch above the tops of the separators.

3. The battery must then stand from 10 to 15 hours before placing on charge.

4. After standing for this length of time, fill each cell again, if necessary, with 1.335 specific gravity electrolyte to bring the level of the electrolyte 3/8 inch above the tops of the separators before charging.

5. Place the battery on charge at the finish rate marked on the name plate until the gravity and cell voltage stop rising. This charging will require at least 48 hours.

6. If, after a charge of 48 hours or longer the specific gravity does not rise for two consecutive hours, the gravity should be between 1.280 and 1.300. If it is not between these limits, the specific gravity should be adjusted to these values at the end of the charge.

7. If, during the charge, the temperature exceeds 110 degrees Fahrenheit, the charge rate should be reduced so as to keep the temperature below 110 degrees Fahrenheit and the time of charging lengthened proportionately.

Preparing Westinghouse Batteries for Service

(These batteries are prepared for shipment in what is known as export condition.)1. Remove vent plugs and discard soft rubber caps.

2. Fill all cells with 1.300 specific gravity sulphuric acid until top of connecting straps, as seen through vent holes are completely covered. Temperature of filling acid should never be above 90 degrees Fahrenheit.

Note: The aim is to fill the cells with acid of such a Specific gravity that the electrolyte, at the end of charge, will need very little adjusting- to bring it to the proper specific gravity.

1.300 specific gravity acid has been found to be approximately correct for this purpose. However, if after several batteries have been prepared for service -using 1.300 specific gravity acid, considerable adjusting at the end of charge is necessary, it is permissible to use a slightly different specific gravity of filling acid, but the use of acid above 1.325 specific gravity or below 1,250 specific gravity is not recommended.

3. Allow batteries to stand after filling for from two to three hours before putting on charge.

4. Put on charge at finish charge rate shown on name plate of battery.

Note: If temperature of electrolyte in battery reaches 100 degrees Fahrenheit (determined by inserting special thermometer through vent hole in cover), the charging rate should be immediately reduced, as continued charging at a temperature above 100 degrees Fahrenheit is injurious to both separators and plates.

5. Continue charging until all cells are gassing freely and individual cell voltage. and specific gravity of electrolyte have shown no decided rise for a period of five hours.

Note: The length of time required to completely charge a new battery depends largely upon the time the battery has been in stock, varying from twelve to twenty-four hours for a comparatively fresh battery to four or five days for a battery six months or more old.

6. Keep level of electrolyte above tops of separators at all times, while charging by adding distilled water to replace that lost by evaporation.

7. After battery is completely charged the specific gravity of electrolyte in all cells should be adjusted to 1.285 at 70 degrees Fahrenheit, and the level of electrolyte adjusted so that after battery is taken off charge the height of electrolyte stands 1/8 inch above tops of connecting straps.

Note: Corrections for temperature if temperature of electrolyte is above or below 70 degrees Fahrenheit the correction is one point of gravity for each three degrees of temperature. See page 65.